About Us

About Us

Wuxi PolySource Geological Equipment Co., Ltd. is a high-tech enterprise specializing in the R&D, manufacturing, and sales of specialized equipment for geological exploration and mining machinery. the company is located at No. 300 Yuexi Road, Ehu Town, Xishan District, Wuxi City. As an emerging force in the industry, PolySource focuses on technological innovation and provides efficient, durable, professional equipment solutions for geological exploration and mining.

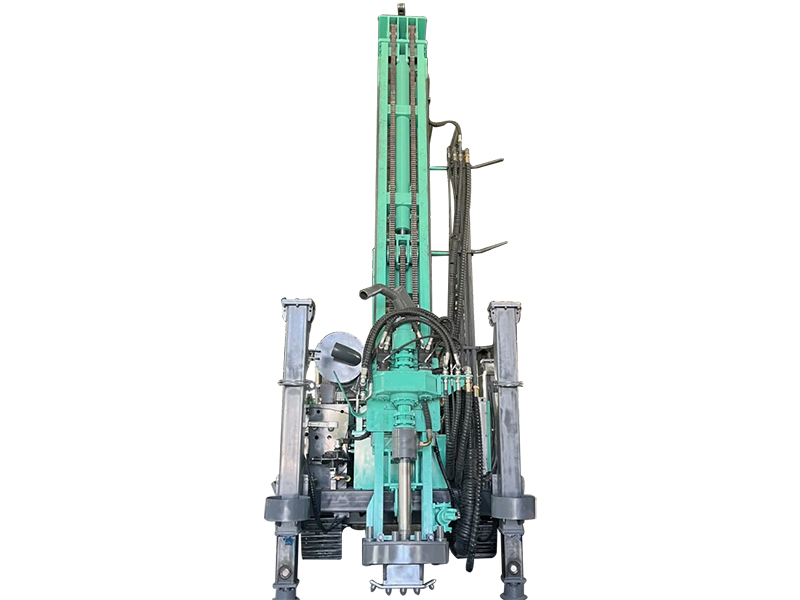

Core Products and Services 1. Geological Exploration Equipment Product Range: Covers geological drilling equipment, geotechnical sampling equipment, suitable for mineral exploration, engineering geological surveys, and environmental monitoring......

Products

Hot Products

Our Advantage

Strong product development capabilities and advanced fabrication equipment, can be customized according to customer's special requirements.

Covers geological drilling equipment, geotechnical sampling equipment,Supporting Equipment for Mining Exploration,Complete sets of wireline drilling tools

Collaborates with universities and research institutions to continuously optimize performance and extend equipment lifespan.

Offers 24-hour technical support, equipment repair, and spare parts supply to ensure efficient customer operations.

Latest News

2026-02-02

In the fields of mining, tunnel excavation, construction, etc., rock drilling is a fundamental and crucial环节. As an efficient impact crushing equipment, the hydraulic rock drill, with its powerful power and stable performance, has become an indispensable tool in modern engineering. This article will detailedly introduce the working principle, main application scenarios, and purchasing points of hydraulic rock drills to help you better understand this equipment. I. Working Principle of Hydraulic Rock Drill: Impact Crushing Mechanism Driven by Hydraulic Energy The core working principle of a hydraulic rock drill is based on ""impact crushing"", and its power source is the hydraulic system. Simply put, the equipment converts mechanical energy into hydraulic energy through a hydraulic pump, and then converts the hydraulic energy into high-frequency and high-intensity impact force through components such as hydraulic cylinders. When the hydraulic oil flows rapidly in the system, it will push the piston inside the rock drill to reciprocate at a high speed, and the piston hits the drill bit, causing the drill bit to produce continuous and intensive impact on the rock. This impact energy overcomes ...

2026-01-30

A core drilling rig is an indispensable piece of equipment in numerous engineering and scientific research fields. Its core function is to precisely drill and obtain cylindrical core samples from various materials of different properties. Unlike traditional drilling methods that rely on impact or cutting, core drilling rigs primarily operate through a precision grinding process. This characteristic allows them to maximize the integrity of core samples while drilling, providing valuable physical evidence for subsequent analysis and research. Main Types of Core Drilling Rigs Core drilling rigs can be categorized into the following types based on their design features and application scenarios: 1. Portable Core Drilling Rigs: These rigs are characterized by their compact size and flexibility, typically designed for handheld operation. They are ideal for use in confined spaces with limited working room or for operations requiring smaller drill hole diameters. Their ease of operation makes them stand out in scenarios needing quick and flexible drilling. 2. Frame-Mounted Core Drilling Rigs: Frame-mounted rigs are more suitable for cutting large structures, such as in construction and civil engineering p...

2026-01-26

Drilling machinery is an indispensable key equipment in modern industrial production. Widely used in numerous fields such as construction, manufacturing, oil and gas, and aerospace, they are employed to precisely and efficiently create round holes in various materials. Choosing the appropriate drilling machinery can not only significantly improve production efficiency but also ensure processing quality and reduce costs. This article will detail the main types of drilling machinery, their application scenarios, and the core factors to consider when making a selection. I. Main Types of Drilling Machinery Drilling machinery can be classified according to different criteria, with common classifications including operation mode, structure, function, and power source. 1. Classification by Operation Mode Manual Drilling Machines: Rely on human operation, have a simple structure, and relatively low cost. They are suitable for simple drilling tasks with low precision requirements and small workloads. Semi-automatic Drilling Machines: Combine the flexibility of manual operation with some advantages of automation, which can reduce manual labor intensity to a certain extent and improve production efficien...

2026-01-23

In the fields of geological exploration and engineering construction, efficient and precise drilling equipment is the core to ensuring the smooth progress of projects. As an advanced geological drilling equipment, the reverse circulation drilling rig has become an ideal choice in many engineering scenarios due to its unique working principle and significant advantages. This article will deeply analyze the working principle, core features and main application fields of reverse circulation drilling rigs to help you fully understand the value of this equipment. Working Principle of Reverse Circulation Drilling Rig: The Perfect Combination of Efficient Crushing and Rapid Cuttings Removal The core advantage of reverse circulation drilling rigs stems from their unique working mechanism. It efficiently crushes the soil and rock at the bottom of the hole through the high-frequency vibration and cutting force of the drill bit; at the same time, with the help of the reverse circulation system, the crushed rock cuttings are quickly and continuously discharged from the bottom of the hole to the surface. This ""crushing-cuttings removal"" simultaneous mode avoids the problem of repeated crushing caused ...

2025-12-05

In building foundation construction scenarios, different types of foundation soils bring varying impacts to drilling operations, and the reverse circulation drill rig needs to make targeted adjustments to deal with these situations. When facing highly cohesive soil, the mud circulation system of the reverse circulation drill rig plays a role. It delivers mud with moderate viscosity to wrap soil particles around the borehole, reducing the adhesion of mud to the inner wall of the drill pipe and preventing borehole blockage caused by soil caking. At the same time, workers will properly control the drilling speed, giving the mud enough time to carry away crushed soil clods and maintaining smooth drilling. When encountering sandy soil, the anti-collapse measures of the reverse circulation drill rig are particularly critical. This type of soil has loose particles, and the borehole wall is easy to collapse. At this time, the drill rig will increase the density of the mud, which forms a protective film on the borehole wall to enhance the stability of the wall. In addition, the drill bit of the reverse circulation drill rig adopts a spiral structure. During drilling, it can not only break the sandy soil but also quickly transport the sandy soi...

2025-12-05

Doing a good job in the daily cleaning of drill pipes is the foundation of maintenance work. After completing a section of drilling operation each time, the surface of the drill pipe will be stained with rock slag and mud. Workers should rinse the drill pipe with a high-pressure water gun in a timely manner, and then wipe the surface dry with a dry cloth. Special attention should be paid to the connecting threads of the drill pipe—residual impurities in the gaps need to be carefully cleaned to prevent these impurities from corroding the drill pipe during storage or affecting the fit degree when the drill pipes are connected later. The inspection of the drill pipe connection parts cannot be neglected. It is necessary to regularly check the usage status of the drill pipe joints. If obvious wear marks or deformation are found on the surface of the joints, new joint parts should be replaced in a timely manner to prevent the drill pipe from falling due to loose joints during operation. At the same time, it is also necessary to check whether there is thread slipping in the connecting threads. Once thread slipping is found, the drill pipe should be repaired or replaced to ensure the stability of the drill pipe after connection and avoi...