Copyright © Wuxi PolySource Geological Equipment Co., Ltd. All Rights Reserved. Web Development by Wangke

Thin-walled impregnated diamond drill bits are efficient drilling tools used in modern construction, installation, municipal construction, and other fields. These drill bits exhibit broad adaptability to hard and brittle materials such as reinforced concrete, building stones, glass, and ceramics. They are primarily used for drilling installation holes for water, electricity, gas, and sanitary pipelines on building components, as well as for engineering sampling drilling. They can also be used for drilling various hard and brittle material products.

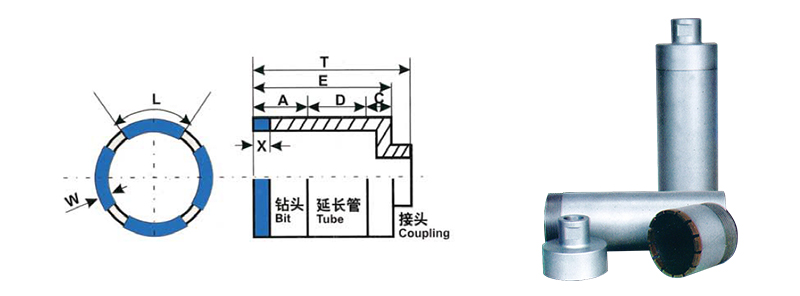

| Size | OD-ID | L | W | X | Bit (mm) | Tube (mm) | Coupling (mm) | Depth (mm) | Length | |

| Inch | mm | mm | mm | mm | mm | A | D | C | E | T |

| 1" | 25.40 | 28.1-19.1 | 13 | 4.5 | 7 | 43 | 230 | 46 | 305 | 365 |

| 11/4" | 31.75 | 33.7-24.7 | 13 | 4.5 | 7 | 47 | 230 | 46 | 310 | 370 |

| 11/2" | 38.10 | 41.1-32.1 | 13 | 4.5 | 7 | 48 | 220 (320) | 46 | 300 (400) | 360 (460) |

| 2" | 50.80 | 53.2-44.2 | 15 | 4.5 | 7 | 48 | 220 (320) | 46 | 300 (400) | 360 (460) |

| 21/2" | 63.50 | 64.8-55.8 | 15 | 4.5 | 7 | 48 | 220 (320) | 46 | 300 (400) | 360 (460) |

| 3" | 76.20 | 77.6-68.6 | 15 | 4.5 | 7 | 48 | 220 (320) | 46 | 300 (400) | 360 (460) |

| 31/2" | 88.90 | 90.1-81.1 | 15 | 4.5 | 7 | 48 | 220 (320) | 46 | 300 (400) | 360 (460) |

| 4" | 101.60 | 110.4-100.4 | 20 | 5 | 7 | 78 | 220 (320) | 46 | 330 (430) | 390 (490) |

| 5" | 127.00 | 128.4-118.4 | 20 | 5 | 7 | 98 | 220 (320) | 46 | 350 (450) | 410 (510) |

| 6" | 152.40 | 160.4-150.4 | 20 | 5 | 7 | 98 | 220 (320) | 46 | 350 (450) | 410 (510) |

| 7" | 177.80 | 180.4-170.4 | 20 | 5 | 7 | 98 | 220 (320) | 46 | 350 (450) | 410 (510) |

| 8" | 203.20 | 205.4-193.4 | 20 | 6 | 7 | 98 | 220 (320) | 46 | 350 (450) | 410 (510) |

| 9" | 228.60 | 230.4-218.4 | 20 | 6 | 7 | 98 | 220 | 46 | 350 | 410 |

| 10" | 254.00 | 255.0-241.0 | 20 | 6 | 7 | 98 | 220 | 46 | 350 | 410 |

| 12" | 304.80 | 306.0-292.5 | 20 | 6 | 7 | 98 | 220 | 46 | 350 | 410 |

| 14" | 355.60 | 356.8-344.8 | 20 | 6 | 7 | 98 | 220 | 46 | 350 | 410 |

|

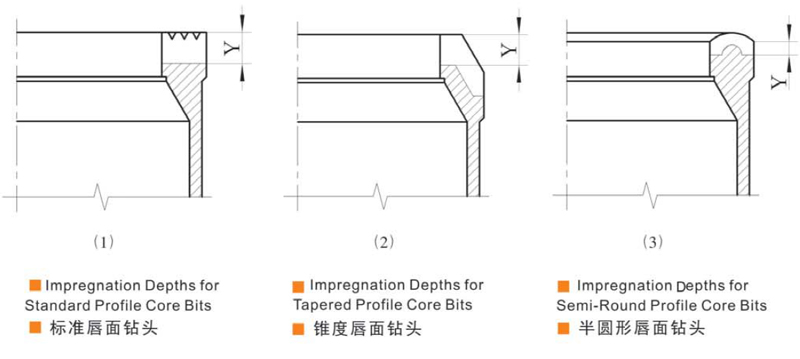

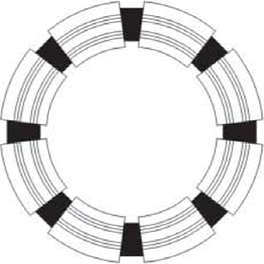

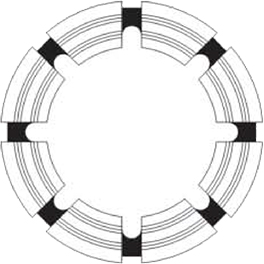

■ Standard design ■ Suitable for a wide range of strata |

|

|

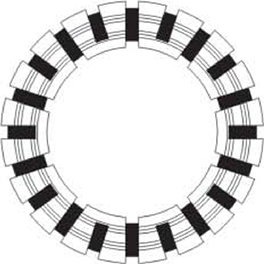

■ It has significantly increased the water flow volume ■ The cutting speed has been improved ■ Suitable for fractured rocks and highly abrasive formations |

|

|

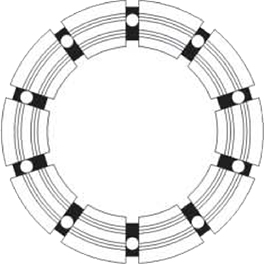

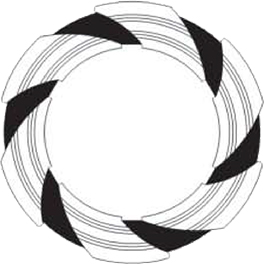

■ Suitable for high-speed cutting and drilling to increase the pressure on the working surface ■ Suitable for hard formations |

|

|

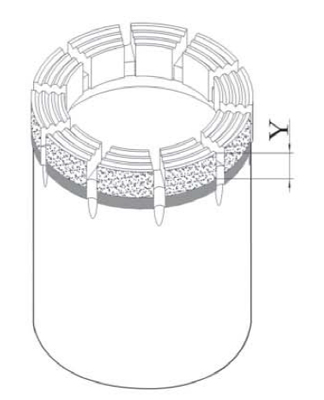

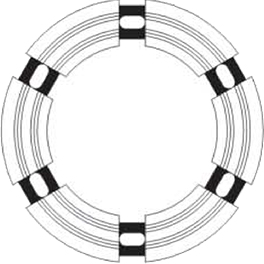

■ This design reduces the scouring effect of water flow on the rock core, thereby enhancing the core recovery rate ■ Suitable for fractured or granular rock formations |

|

|

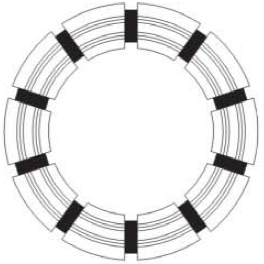

■ Suitable for fragmented sedimentary or deformed strata ■ The water hole in a waist shape has better water flow efficiency than the circular one, and it can more effectively prevent water blockage and drill burning |

|

|

■ This design combines the advantages of a standard lip surface and a bottom-spray lip surface, featuring a simple and reliable process ■ Suitable for broken or hard formations |

|

|

■ Improve work efficiency by reducing the interaction time between the hole and the core ■ Suitable for softer to medium-hard formations |

|